We repair all major industrial HVAC systems including rooftop units, split systems, chillers, cooling towers, boilers, heat pumps, and specialized ventilation equipment. Our experience covers leading brands like Carrier, Trane, York, Lennox, Goodman, and other manufacturers common in industrial settings.

Industrial facilities often require specialized climate control for applications like clean rooms, server cooling, or temperature-sensitive processes. We handle these demanding applications along with standard comfort heating and cooling systems throughout your facility.

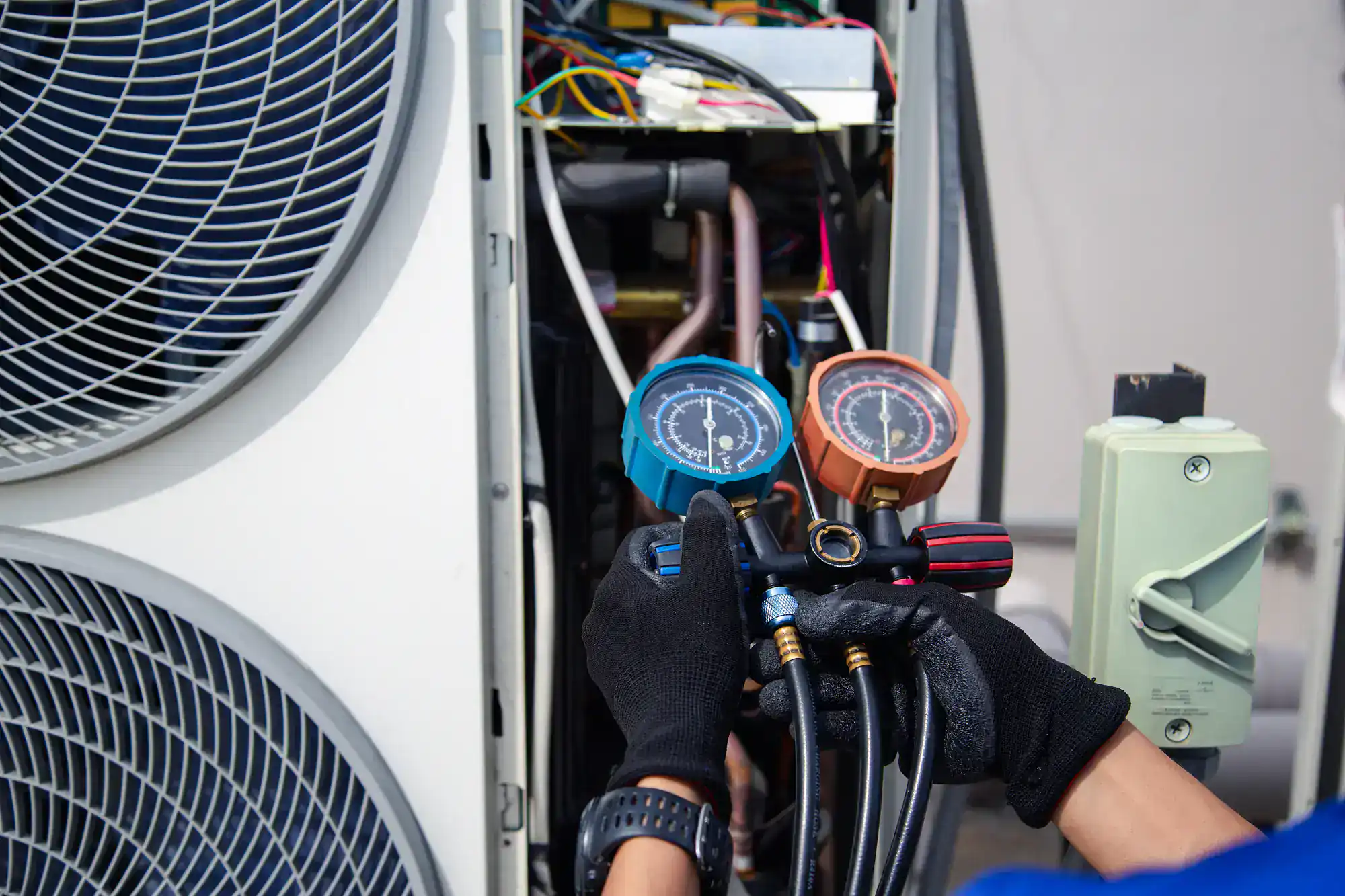

Our service extends to supporting components including ductwork, air handlers, compressors, control systems, and filtration equipment. Many HVAC problems originate in these supporting systems rather than main units, so comprehensive diagnostic capability is essential for effective long-term repairs.